What We Do

NorthStar MedTech Solutions brings results.

Laser Processing of Metals and Polymers

Harness the power of precision. Our laser systems deliver unmatched accuracy for cutting, welding, drilling, and shaping complex geometries in both metallic and polymer-based materials.

For metals, we create the precision-cut hypo-tubes and welds that form the backbone of steerable catheters and other minimally invasive instruments—balancing strength, flexibility, and control. For polymers, we enable micro-drilling, ablation, and joining for MRI-safe and fluid-control components, achieving ultra-clean results for complex catheter designs.

Black Marking of IPG Cases, Stainless Steel, and Titanium

Next-generation black marking technology creates high-contrast, corrosion-resistant, and permanent identification—ensuring performance, durability, and traceability in critical applications such as implantable and surgical components.

Using advanced laser technology, we produce deep, ultra-dark marks for logos, serial numbers, part identifiers, and orientation or depth indicators — all with crisp definition and exceptional readability. Our black marking process alters the metal surface at the micro level without removing material. The result is a smooth, corrosion-resistant, and permanent mark that withstands sterilization, handling, and wear — ideal for surgical tools, implants, and precision assemblies.

Close Tolerance Manufacturing / Micro-Manufacturing

Where precision meets possibility. Our micro-scale manufacturing processes achieve ultra-fine features and tight tolerances essential to miniaturized medical devices.

Unlike traditional machining, which uses physical tools, laser micro machining removes material through focused light energy. This allows us to cut ultra-fine features, create tight inside corners, or form channels within thin-walled tubing — all with micron-level accuracy and no risk of part distortion. In medical device applications, this process enables the creation of complex microstructures that are essential to catheters, guide tubes, and other minimally invasive devices.

Contract Manufacturing – Components & Sub-assemblies

Accelerate innovation with flexible manufacturing support. We partner from early development through full-scale production—streamlining timelines without compromising quality.

We specialize in manufacturing high-precision components that form the core of minimally invasive and implantable devices, using advanced laser and micro manufacturing technologies to meet tight tolerances and demanding specifications. As we expand into sub-assembly manufacturing, Northstar brings the same focus on process control, documentation, and quality assurance required by the most regulated MedTech environments.

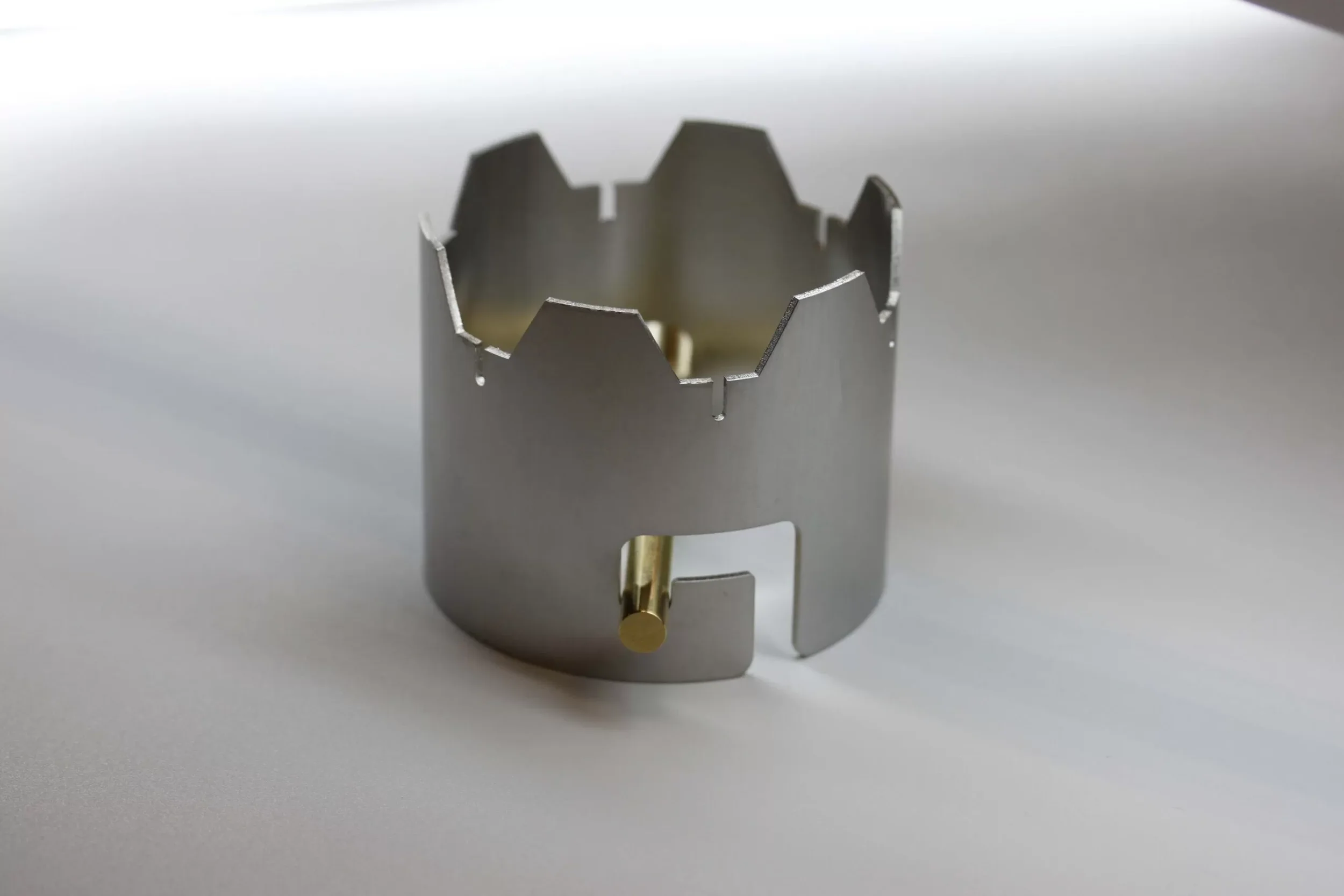

Hypo-tube Cutting

Advanced laser cutting for hypo-tubes and tubular components, achieving clean edges and consistent inner and outer diameters. Consistent, burr-free edges and precise geometries delivered every time.

We specialize in laser-cut hypo-tubes, a critical component in steerable catheters and other minimally invasive medical devices. Our hypo-tube cutting capabilities give device designers the mechanical performance and reliability needed for these critical delivery systems, while maintaining tight tolerances and consistency for every part.

Laser Marking & Ablation

From functional texturing to high-resolution marking, our laser ablation solutions enhance performance, identification, and compliance across complex device surfaces, delivering device functionality, branding, and regulatory compliance.

We offer precision laser marking for medical device components, providing clear, consistent, and traceable identifiers. Laser marking can use infrared (IR) or ultraviolet (UV) laser technologies to create radial lines, serial numbers, logos, or orientation marks on both metals and polymers. Laser ablation is used to precisely remove material from medical device components, whether it’s a metal coating, polymer layer, or part of a structural element.

Low-Cost Manufacturing Options

Innovation shouldn’t come at a premium. Our optimized, scalable production models provide cost-effective solutions—empowering rapid growth without sacrificing precision. Our production models maintain the highest standards of quality and precision while supporting your commercial goals.

Our automated processes reduce operator variability, ensuring consistent quality, tight tolerances, and low fallout while keeping production costs competitive. The result is a reliable, repeatable, and efficient manufacturing partner that helps device innovators bring products to market faster, smarter, and more affordably.

Industrial & Commercial Applications

While medical devices are our primary focus, Northstar Medtech’s laser and micro-manufacturing capabilities extend to industrial, consumer, and commercial markets. From high-contrast black marking on machine parts to serial numbers, logos, and functional markings on consumer products, our laser systems deliver precision, repeatability, and efficiency for a wide variety of non-medical applications.

Whether it’s custom components, automated marking, or specialized micro-machining, our team brings the same quality, control, and expertise that we apply to medical devices — helping businesses across industries improve performance, reduce costs, and scale production.